April 16, 2015

All efforts of a new player at such market as a membranes market should be aimed to achieve one of the main goals - confirming quality of its product from which quality of millions of cubic meters of water used in industry and population high quality drinking water supplying depends directly.

As a minimum, new supplier entry to the market should be confirmed by operational characteristics which were available for the consumers during last decades and allowed him/her to accomplish its important tasks. That is why, we at “RM Nanotech”, paid huge attention to the quality confirmation of our membrane elements by end-users operational tests at some particular sites and also by comparative testing with foreign manufacture’s products introduced at the Russian market.

The most straight and fair way to scale competitor’s quality is to equally confirm quality of all products introduced at the market. That is why “RM Nanotech” appreciated invitation to participate in parallel testing of membrane elements sold in Russia.

Tests were organized by All-Russian research thermal engineering institute (leading research and engineering center in thermal energy and technologies) upon request of JSC “Inter RAO” which is the major Russian Energy Holding company managing generating assets in Russia, CIS countries and Europe. Moderator and participants have coordinated test’s procedures and results calculation and report. Test uniform conditions which were not contradicting to the standards of the participants were selected based on different company’s recommendations.

“RM Nanotech” test facility was chosen as the only capable to provide required conditions after analysis of all options for parallel testing venue. All procedures starting from unpacking to result’s analysis were conducted in presence of Hydranautics and General Electric company’s representatives.

The following testing conditions were used:

Duration: 48 hours

Model solution: 1500 ppm NaCl

Pressure: 225 psi

Temperature: 25С

SDI : < 5

рН : 7,5

Recovery: 15%

The following membrane elements were picked in a random manner:

GE Osmonics AG-400

Hydranuatics CPA3

DOW Filmtec BW30-400, BW30HR-440i

Hydramem (IonExchange membranes) HM8040BWD365

Toray TM720-440, TM720C-430

RM Nanotech K-8040-C

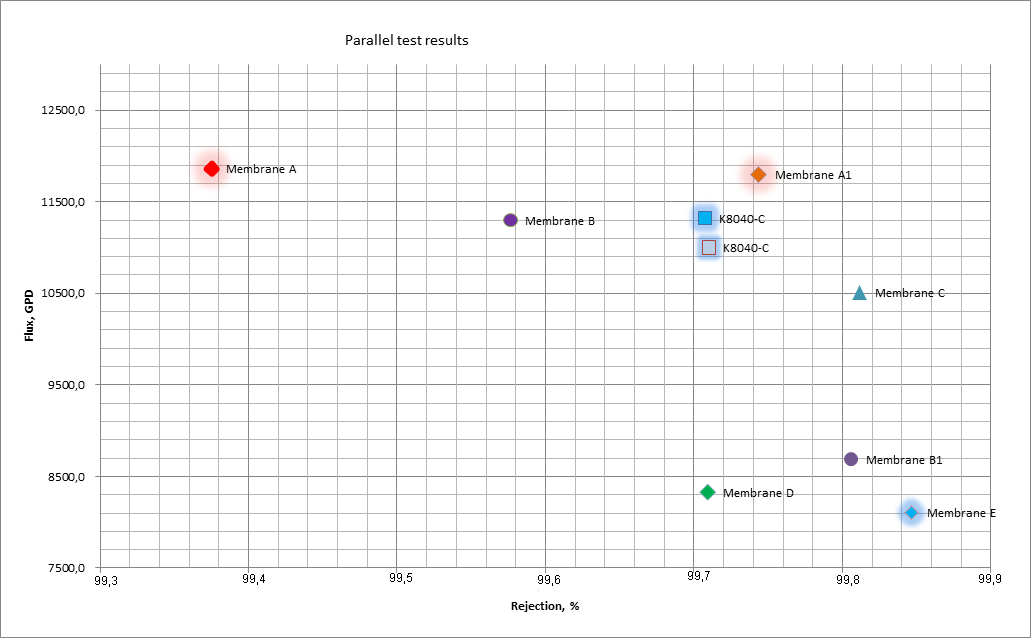

The following results were achieved by above-mentioned membrane elements:

All participants (supplier companies’ representatives in Russian Federation) expressed their satisfaction for parallel test organization and confirmed used testing procedures validity, results fair and prejudice absence while received data analysis.

“RM Nanotech” as the only domestic manufacture confirmed high level of its technologies and its staff high professional qualification.